Firestopping is both simple and complicated. It’s simple in that the principle is straightforward – where a fire compartment is breached, fire-resistant material capable of completely sealing the gap must be used to ensure the integrity of the compartment. Where it becomes complicated is if unsuitable material is used, or is applied incorrectly.

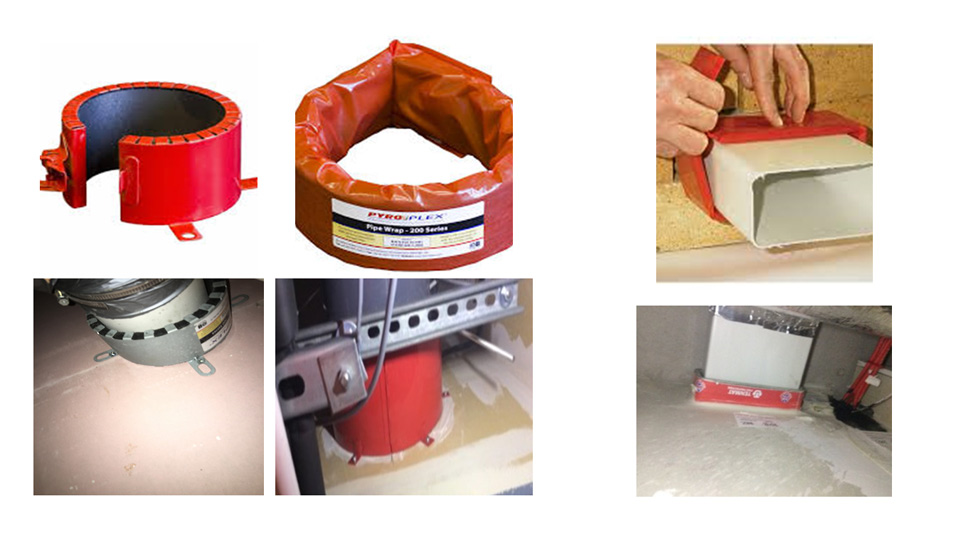

Firestopping materials are products that form permanent seals that plug gaps, no matter how small, between fire compartments. Gaps occur when services pass through the barrier, such as pipework, ductwork and more. Fire stopping materials include things like specialist foam, fillers, sleeves and collars.

Gap-fillers and the misnomer of fire-rated foam

Many of us are familiar with expanding foam – it gets into all sorts of odd little gaps and fissures to form a solid seal, preventing draughts and providing sound insulation. There are many foam filler products available which are fire-retardant, but beware! PU foam filler, which is often bubble-gum pink, is fire retardant, but not suitable for repairing the fire compartment.

These foams are not manufactured for the purpose of fire stopping and therefore have not been tested for fire rating. The fire rating of your repair materials must match the fire rating of the compartment.

Where expanding foam is needed, some major manufacturer have produced specialist foams which have some merit – but these should be used in conjunction with other fire stopping materials, such as Gypsum based mortar, instumastic acrylic sealant and fire-rated batt.

Sleeves and collars

Where a pipe passes through a barrier, fire sleeves or collars may be used. Fire sleeves are fitted to the aperture, so cables as well as pipes may pass through, whereas collars are fitted around the pipes themselves. In the event of a fire, a collar will expand to seal the opening and a sleeve will crush the pipe.

Cavity barriers

Where different types of materials meet – brickwork and plasterboard, for example –fire-resistant mineral wool batts are useful for sealing the gaps.

Curtain barriers

You might have seen a safety curtain in a large theatre – it is intended to prevent fires starting onstage from affecting the auditorium, allowing time for safe evacuation of the building. Fire curtains used in buildings work in much the same way.

They can be fitted in ceiling voids or under raised access flooring, as permanent fixtures. They can also be stored at ceiling level in a head box, ready to be dropped in the event of fire to prevent the spread of flames, heat, gases and smoke. Used in this way they can prevent the spread of fire in large open areas, such as warehouses or arenas, by effectively compartmentalising them. This can create protected escape routes and make it safer for the fire service to access the building.

Correct usage is the key

A range of fire-stopping materials exists, making it possible to reseal a breached fire compartment in any circumstances. The trick is making sure the right materials, fire-resistant to the right level, are used appropriately and fitted by competent people.

Fire stopping around fire and smoke dampers

Fire and smoke dampers are fitted in ductwork precisely where it breaches a fire compartment. It is essential that when inspecting and testing dampers the surrounding area is also checked. Any breaches in the fire compartment must be remedied for the installation to be considered safe.

If you require help with fire and smoke damper inspection and testing, or remedial works required to achieve compliance, get in touch. Our experts are ready to help.